| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : ZSON

Model Number : ZS-8040M + ZS8060PE

Certification : CE

Place of Origin : China

MOQ : One Set

Price : Negotiated

Supply Ability : 1 Set: 10 Days / 2-5 Set: 15 Days / 6-10 Set: 25 Days / >10 Set: Negotiated

Delivery Time : 15 Working Days

Packaging Details : Standrad Wooden Case For Export

Power Source : 3P AC380V 2.2KW+28KW

Modes of Packing : Sleeve Sealing

Service Time : 1 Year Warranty

Cargo Ready : 15 Working Days

Application : Mineral Water Plastic Bottle

Packaging Speed : 30M / Min

Size Range : L600 x W650 x H350MM

Customization : Logo / Color/ Size / Voltage / Material / Parts Brand

Auto PE Shrink Film Wrapping Packaging Machine

Product Feature

ZS-8044M+ZS8060PE is a cuff full automatic wrapping machine, It is designed specifically for single or products with bottom board. The machine can be connected with the production line to achieve automatic feeding, wrapping, sealing, shrinking, cooling and shaping.

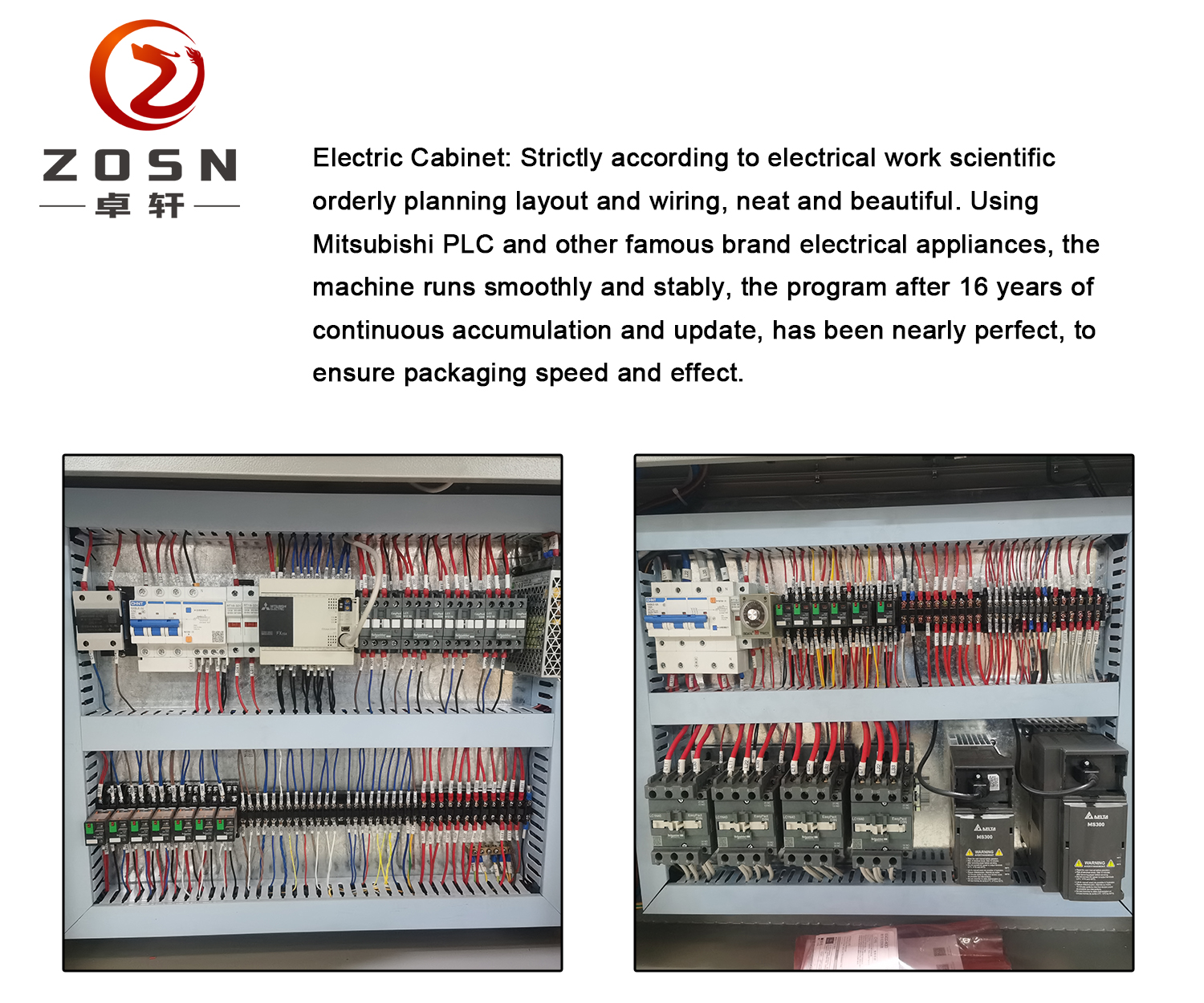

ZS-8040M has introduced advanced technology and production process to ensure stable and reliable performance. Induction film feeding greatly reduces the loss of film. Digital display temperature controller can accurately control the temperature and can be seen it directly. Machine is controlled by Mitsubishi programmable controller to achieve mechanical, electrical and pneumatic stability. Three pieces sealing knife is designed specifically for perfect sealing. The feeding belt can be designed to feed on the left or the right side as required.

ZS-8060PE uses four wind motors to make the hot air in tunnel distribute evenly, Super-large cold airflow makes the products cooling and shaping quickly after shrinking. The conveying line is controlled by Delta frequency converter.

1. This machine can collate bottles (round or square), cans, gable cartons, and tetra cartons automatically. it can connect filling machine or labelling machine to make production line unmanned.

2. Bottles can be collated faster by a special faster and stable collating device and never fall down.

3. Adopt durable “u” shape alloyed sealing knife and saw teeth cutting knife with anti-stick Teflon coats supported by four columns, the sealing line is very strong and can use thicker pe film for heavy products.

4. Rows can be set on the touch screen. when product size changes only adjust packing size on the machine within a short time without changing any molds.

5. Adopt Siemens plc and colorful touch screen, Omron temperature controller, timer, relay, switch, and sensor.

6. Optional output roller table or conveyors are available.

7. Optional safety cover is available.

Descriptions of Product

| Model | ZS-8040M | ZS-8060PE |

| Power | 2.2KW | 28KW |

| Power Supply | AC380V 3P 50/60Hz | AC380V 3P 50/60Hz |

| Max Packing Size L x W x H | 600 x 650 x 350MM | 1500 x 600 x 500MM |

| Tunnel Size L x W x H | / | 1800 x 800 x 600 MM |

| Blade Length | 800MM / 400MM | / |

| Air Temperature | 0-300℃ | 0-300℃ |

| Table Height | 825 ±50MM | 825±50MM |

| Packing Speed | 0-30M / Min | 0 - 30M / Min |

| External Air Source | 6-8KG / CM2 | / |

| Shrink Film | PE | PE |

| Machine Size L x W x H | 2500 X 2260 X 2030MM | 3000 X 1320 X 1780MM |

| G / N Weight | 520 / 460KGS | 720 / 650KGS |

Products Display

Features / Brands:

| Parts | Particulars | Technical parameter description | |

| Power source | 380V/3PH/50Hz ≤2.2KW, | ||

|

Sealing system

| Thermal source | Metal strip heat pipe | |

| Sealing knife | Stick resistant and temperature resistance of copper seal knife plated with Teflon on surface | ||

| Temperature control of seal knife | Temperature controlled in 0-200℃ by digital display temperature controller and thermal induction Brand: OMRON | ||

| Sealing size | Maximum width dimensions: width+height > 600mm | ||

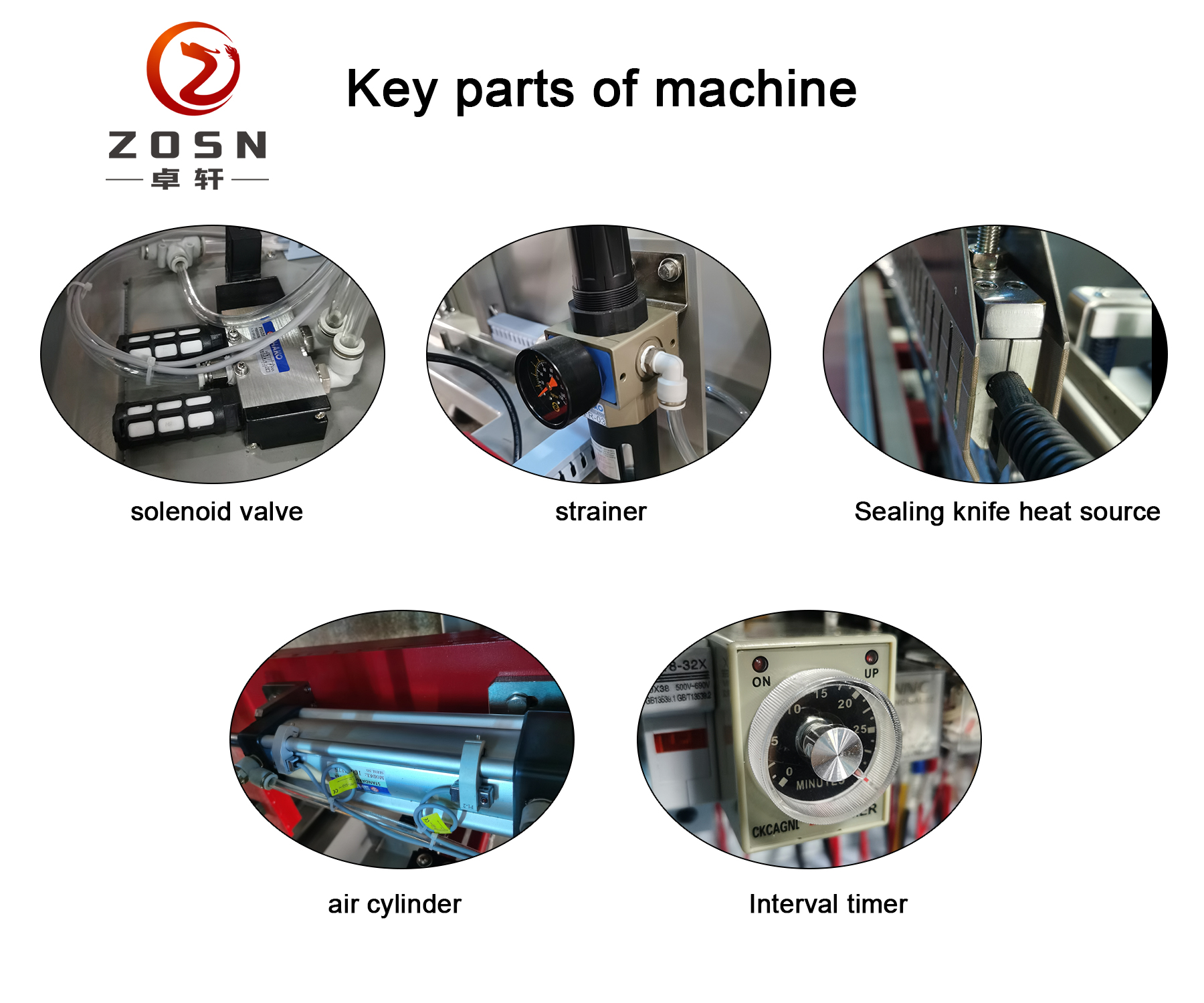

| Cylinder | Brand: Air TAC | ||

|

Delivery system | Belt | High-speed and wear-resistant antistatic conveyor belt | |

| Motor Button switch | Taiwan Stone Germany Muller Ensure delivery smoothly | ||

| Feeding film system | Motor | Brand: VTV Ensure delivery smoothly | |

| Inductive | Brand: RSK Accurately control the length of feeding film | ||

| PLC, HMI | Brand: Mitsubishi & Samkoon | ||

| Relay AC Contactor | Taiwan Stone Schneider | ||

| Mechanism material | The shell is dusted with carbon steel, the thickness not be less than 1mm, the key parts are made of stainless steel plate and aluminum profile. Machine structure is solid | ||

| Machine dimension | L2500*W2260*H20300(ZT-8040M); | ||

| Air pressure | 6 BAR, | ||

| Surface treatment | Chromium plating on the surface of each corrosible structural material, the surface of aluminum alloy is oxidized. | ||

Packaging And Delivery

1. Spray anti-rust oil

2. Fix the machine on the pallet

3. The machine is also wrapped with stretch film and sponge pads, prevent the machine from impact, moisture, dust

4. Covered with sea export plywood case.

5. Port Guangzhou or Shenzhen

|

|

30M/Min Sleeve Wrapping Machine Images |